Introduction to Pipe Relining

Pipe relining, an environmentally responsible and trenchless method, repairs pipes without excavation and is increasingly favoured for its cost-efficiency compared to traditional pipe replacement.

Utilising a pliable epoxy resin, this method inserts a lining into the existing pipe, forming a new interior at a lower cost than traditional replacements. Relining revitalises ageing pipes, providing enduring functionality and notable cost reductions compared to complete pipe replacement.

We employ top-tier epoxy resins and linings for pipe relining, ensuring our customers receive the best possible solutions.

This overview provides key insights on pipe relining materials and quality to guide your informed decisions on pipe repairs. Coogee Plumbing, as a leader in plumbing solutions, recognises the significance of premium materials for enduring repairs to damaged pipes.

Common Pipe Relining Materials Used

Epoxy resin is the go-to relining material due to its strength, durability and chemical resistance properties. Epoxy is flexible enough to mould tightly to the inner walls of pipes, creating a seamless new barrier. It creates a durable protective layer inside old pipes, suitable for various materials, including clay, concrete, PVC and cast iron, and can withstand your hot water system’s demands.

- PVC (polyvinyl chloride) – a lightweight plastic suitable for hot and cold potable water applications. PVC pipe relining is often used as a replacement for failing galvanised steel pipes.

- HDPE (high-density polyethylene) – A flexible plastic resistant to chemicals and corrosion, commonly used in drain cleaning and relining larger drain pipes.

The choice of relining material depends on factors like the original piping material, pressure ratings, access, and environmental conditions. Our plumbers expertly assess these factors to ensure the most appropriate relining solution for your needs.

At Coogee Plumbing, we exclusively use 100% solids epoxy resins which contain no volatile organic compounds (VOCs). Our approach ensures that pipes have a safe, stable, and non-toxic lining, preserving the quality of drinking water.

Epoxy Resin

For Brisbane plumbing projects advocating green solutions, epoxy resin has emerged as the preferred relining material, thanks to its superior durability, malleability, and chemical resistance.

Our pipe relining service employs a thermoset plastic, composed of an epoxy resin and polyamine hardener. When combined, these form a tough, rigid lining that binds tenaciously to the inside walls of any plumbing pipe. Epoxy linings withstand elevated temperatures, pressures, and corrosion, surpassing alternative pipe relining options.

The primary advantages of epoxy resin for pipe relining include:

- Extremely strong adhesion to pipe walls for a seamless structural reinforcement.

- Total barrier protection against leaks, roots, corrosion and erosion.

- Withstands hot water temperatures up to 140°C.

- Long service life of 50+ years.

- Food-safe and non-toxic.

Epoxy resin linings are particularly suited for sewer pipes repair, effectively prolonging the functional lifespan of ageing pipes by sealing damage and fortifying structural stability. While the initial investment may be higher, our epoxy-based relining services are cost-effective over time due to the extended lifespan of the refurbished pipes.

Pipe relining work backed by long-term guarantees of 15 or more years.

For exceptional pipe refurbishment that stands the test of time, count on our skilled team’s high-quality epoxy resin linings.

Cured-In-Place Pipe Lining

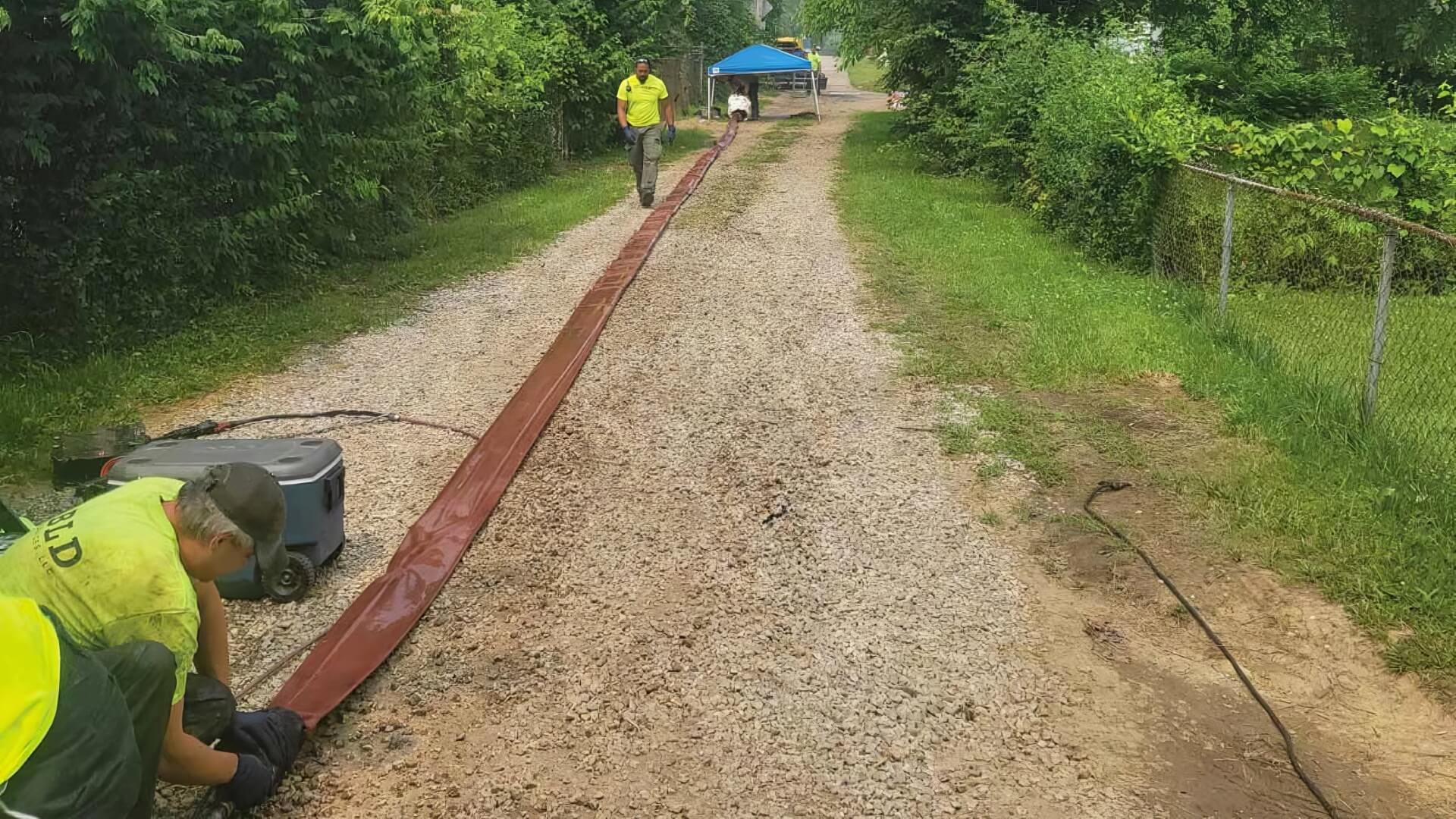

Cured-in-place pipe (CIPP) lining, which does pipe relining seamlessly, is a popular trenchless technique that involves installing a resin-impregnated liner inside the existing pipe to form a new pipe.

This non-invasive technique preserves your yard and pavement by eliminating the need for excavation. The epoxy-coated resin liner is inserted into the original pipe, improving your property’s plumbing through existing access points. It is then expanded and cured using hot water or steam to harden against the old pipe walls.

Cured-in-place sewer pipe relining furnishes a jointless and seamless solution for your sewer line, utilising epoxy resin that robustly bonds, forming a stalwart interior bulwark. It restores structural stability, seals leaks and protects against corrosion or erosion.

Key benefits of CIPP pipe relining include:

- Much faster and less disruptive than digging and replacing pipes

- Effectively renews old piping systems with minimal surface impact

- Long-term fix restoring full flow capacity

- Resin liners can last 50 years or longer

- Cost-effective compared to full pipe replacement

At Coogee Plumbing, we use industry-leading CIPP relining products and experienced technicians to deliver optimal pipe remediation solutions.

Our company guarantees your pipe relining services for over 15 years, with comprehensive CCTV inspections to confirm quality. For non-invasive solutions adeptly navigating and repairing drain issues, call us and place your confidence in our expert team.

Assessing Pipe Health Non-Invasively

Non-invasive camera inspection using CCTV cameras are an essential part of determining overall pipe health and deciding when to repair drains with suitability for relining.

Operating a camera through the pipes offers clarity in identifying damages, blockages, or tree root invasions. This minimally disruptive diagnostic procedure concludes with a clean-up, ensuring fully functional and unobstructed drains.

CCTV inspections provide detailed assessments of your sewer’s condition:

- The exact condition of pipes

- What sections need repairs

- The best repair method for each section

- The materials required for relining

We only reline pipes suitable for epoxy resin liners and inform you upfront if full replacement is required.

The advantages of CCTV drainage inspections are as follows:

- Precision identification of all defects along the pipe

- Avoiding unnecessary excavation

- Ability to reline selected sections as needed

- Monitoring liner installation and post-cure results

Coogee Plumbing offers long-term guarantees on our professional workmanship. Our CCTV checks validate proper resin curing and bonding, ensuring your blocked drain issues are resolved with confidence in your relining project.

For non-invasive pipe health assessments and adept relining services, accommodating the specific requirements of the eastern suburbs, reach out to the trenchless repair experts today.

Factors Determining Pipe Relining Quality

There are several key factors that influence the overall quality and success of a pipe relining project:

Condition of Original Pipes

During CCTV inspections, the existing pipe’s condition is scrutinised, which can reveal essential data for the relining process. Pipes with severe damage, deformation or heavy encrustation may not be suitable candidates for the best pipe relining methods. The epoxy liner relies on smooth inner pipe walls for proper bonding and curing.

Pipe Access

Our experts excel in accurately guiding the resin-saturated liner throughout the pipe, foreseeing and mitigating potential issues. Pipes with numerous bends, sags, or obstacles can hinder what you need to know and expect from optimal pipe relining installation practices.

Resin Quality

Relining utilises 100% solids epoxy resins, known for their superior strength, adhesion, and durability. Inferior resins risk potential cracking or detachment issues down the road.

Proper Installation

Our NATA-certified technicians come highly recommended, and we would certainly recommend them, thoroughly educated and prepared to meticulously perform drain relining procedures, which are carried out under stringent protocols. We vouch for procedures of proper impregnation, inversion, curing, and post-assessment procedures, recommend them for a high-calibre relining process and outcome.

Curing Thoroughness

CCTV inspections validate the liner has cured evenly and bonded fully to the pipe walls. Any uncured spots or delamination would compromise liner integrity.

Through careful attention to these essential factors, Coogee Plumbing provides dependable and durable pipe relining.

Choosing a Certified Professional Contractor

Selecting a certified and seasoned contractor for your pipe relining assures dependable, top-quality outcomes.

Ensure the job done is exemplary by verifying the subsequent credentials and expertise:

- Licencing - All plumbers must be fully licenced in your state to work legally on plumbing projects.

- Industry Certifications - Look for accreditations from bodies like the National Association of Pipe Relining Contractors (NAPRC).

- Proper Insurance - Contractors should carry adequate public liability and workers’ compensation policies.

- Training & Experience - Prefer contractors with a specialisation and training in trenchless pipe relining, boasting a history of successful projects.

- Equipment & Materials - They should use industry-leading CCTV inspection equipment and 100% epoxy resin products proven to last.

- Warranties - Well-established companies offer transferable long-term warranties of 10 or more years on relining workmanship.

- Reputation - Check reviews and testimonials to verify quality of service from past customers.

Meticulous research and assessment of contractors ensure quality repairs, fostering trust for any future plumbing needs. At Coogee Plumbing, Our certified plumbing professionals simplify the process by providing a comprehensive free quote that exceeds industry benchmarks.

Checking Credentials and Warranties

When hiring your plumber as a contractor for pipe relining, it is crucial to verify their credentials and seek warranties for peace of mind and assurance of quality work.

Licencing and Insurance

Always confirm plumbing contractors have up-to-date licences for your state and carry adequate insurance like public liability cover. Licenced, insured plumbers demonstrate credibility and accountability.

Industry Certifications

Look for recognised industry certifications like ones from the National Association of Pipe Relining Contractors (NAPRC). This indicates advanced training and compliance with strict quality standards.

Experience and Training

Opt for an experienced company specialised in pipe relining specifically. Ask about the training and qualifications of technicians who will perform the relining. Expertise ensures a quality installation.

Product Warranties

Reputable contractors offer long warranties on products used, often 50+ years for epoxy liners. This provides assurance the materials used are high-quality and durable.

Workmanship Guarantees

Look for substantial workmanship guarantees of 10+ years on the pipe relining application. This demonstrates the company stands behind their expertise and service quality.

Taking time to validate credentials and secure warranties gives you confidence in a relining business’ expertise and assurance of long-lasting results. Contact us today to learn more.

Cost Analysis of Relining vs Replacement

When faced with damaged or deteriorating pipes, homeowners must decide whether to reline the pipes or can also consider fully replacing them. Cost is often a major factor in this decision.

Pipe relining typically costs between $80 and $250 per metre, significantly less than the $400 to $1000 per metre for pipe replacement. Relining, including solutions for storm water systems, is therefore often 60-90% cheaper than replacing pipes.

However, to learn more about cost savings from relining, keep in mind they diminish for larger pipe diameters. Replacement may be only 2-3 times more expensive for pipes over 300mm wide. You need to know the professional advice on the best value option for your specific plumbing needs.

While cost-effective with an impressive 50-year lifespan, pipe relining can be initially expensive compared to the 80+ years expected of new pipes. Periodic maintenance may be required over time.

There are also further cost considerations beyond material expenses. Relining avoids the major excavation, property damage, and landscaping costs of replacing buried pipes. It also minimises disruption to your home or business operations.

Ultimately, a long-term cost-benefit analysis weighing all factors will determine if pipe relining or full replacement makes better economic sense for specific projects.

Coogee Plumbing’s licensed experts offer clear, transparent quotes and concise explanations for all repair options. We identify the cost pipe relining and the most cost-effective trenchless or full replacement solutions tailored to your needs and budget.

Conclusion

Assessing whether pipe relining is worth the investment should be straightforward when one acknowledges its benefits in restoring and extending the utility of your plumbing system in a non-invasive, cost-effective manner. However, knowing what each material does, quality materials and professional installation are crucial for it to be an effective, long-term solution.

As outlined, the pipe relining process, ideal for any damaged pipe, involving 100% epoxy resin liners, provides the greatest durability, longevity and pipe bonding. Meanwhile, factors like proper pipe access, resin saturation and curing validation also determine the integrity of the finished liner. Hiring certified, experienced contractors for assessment and installation is highly recommended.

Coogee Plumbing stands out as a connoisseur of high-quality pipe relining solutions, with our adept use of leading CCTV inspections, first-rate epoxy products, and refined techniques. For top-tier pipe relining Sydney services available hours day 7 days a week to rejuvenate your pipes non-invasively, call us any time at 1300 349 338 or email us at [email protected]. Our team is ready to inspect your pipes and recommend the best options to suit your needs.

Our responsive team provides long-term guarantees backed by our extensive expertise in plumbing.