Introduction to Pipe Relining

Pipe relining is an essential upgrade for ageing plumbing systems, offering a non-disruptive solution, especially in areas like Coogee, Sydney. This method avoids yard excavation and is more cost-effective than traditional pipe replacement.

In pipe relining, a flexible epoxy resin pipe liner is inserted into the existing pipe and cured to form a smooth new pipe lining. The new lining restores flow capacity and seals leaks in existing pipes without requiring excavation or surface demolition.

In this article, we’ll take a comprehensive look at relining - how it works, key benefits compared to replacement, when it’s recommended, and what to expect from the no-dig process.

Read on to learn why we would highly recommend pipe relining as part of any plumbing upgrade or maintenance plan for your property. We’ll also cover signs your pipes may need relining, and why it’s wise to address issues early before pipe failure damages your home or property.

What is Pipe Relining and How Does it Work?

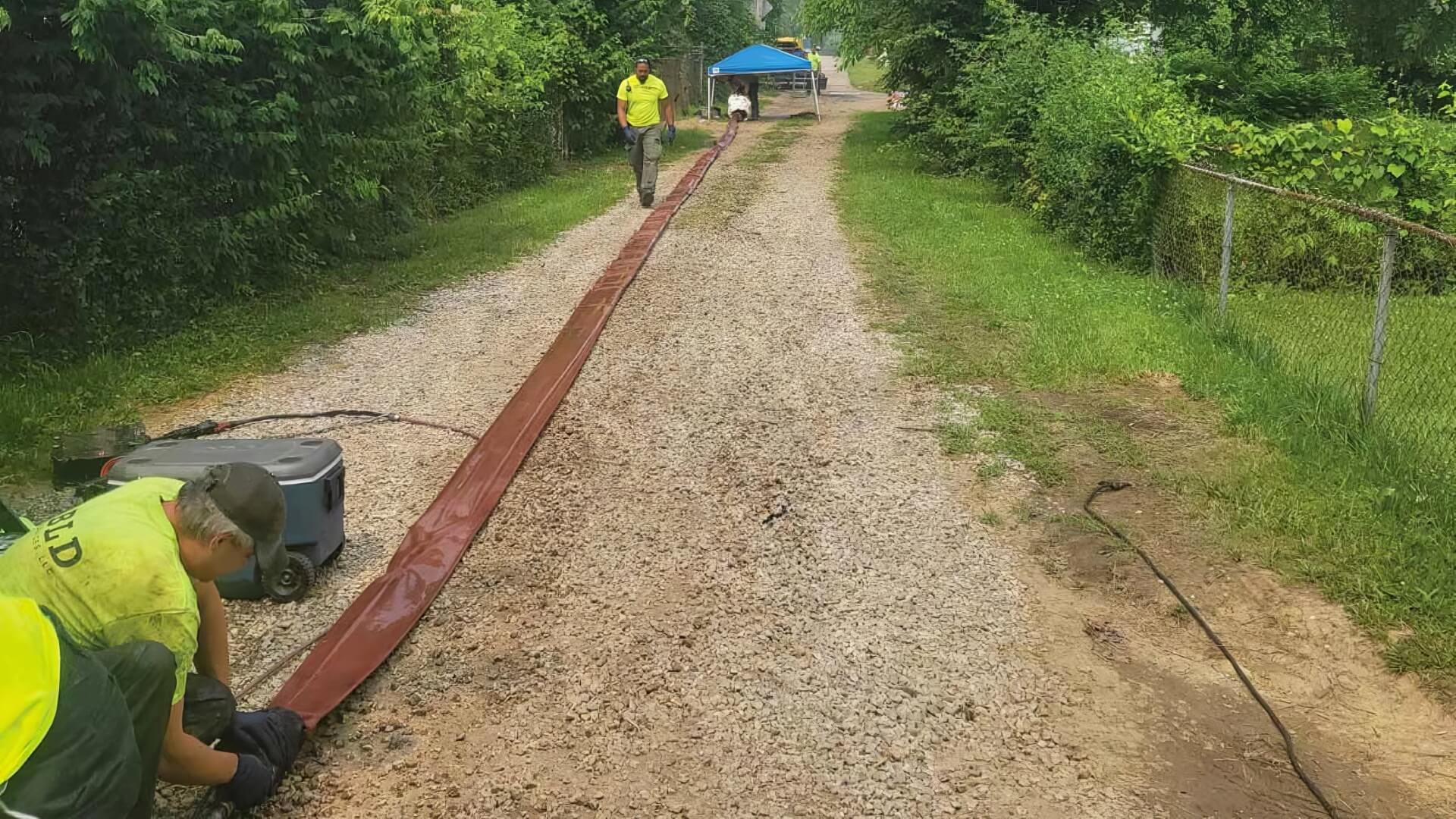

Pipe relining, a no-dig repair method, involves inserting an epoxy resin liner into damaged pipes to create a new pipe. Utilising CCTV technology, this process includes an inspection of the pipe’s interior to determine the damage extent and location.

Following damage assessment, a flexible liner soaked in epoxy resin is fed through the pipe and inflated against your old pipe’s walls, before the site is restored.

The cured resin forms a seamless, corrosion-resistant lining that adheres to the old pipe. Pipe relining can be accomplished within the system without digging as no excavation or destruction that could disrupt your surfaces is required, with access gained through outside cleanouts or inside drain lines.

Pipe relining restores drainage and water flow as it covers obstructions, cracks, and root intrusions with a new epoxy liner inside the existing pipe. It also seals leaks and prevents further corrosion. Relining is versatile, suitable for sewer and stormwater drains, galvanised iron and other pipes.

Pipe relining proves to be faster, less invasive and more economical than traditional pipe replacement. The cured liner also has a typical lifetime matching PVC so it’s a long-term solution.

When you have a blocked drain or ageing pipes show signs of damage like leaks and rust, contact our professional plumbing services to see if relining is the best repair approach. We come out to all areas across Sydney including Coogee and can perform pipe relining sydney-wide, doing a great job of sewer repair by relining your pipes with minimal fuss.

Advantages of Trenchless Pipe Relining vs Traditional Replacement

- Cost-efficiency - Relining is generally 50-80% more cost-effective than full pipe replacement.

- Less disruptive - It avoids the need for trench digging and surface demolition.

- Faster installation - The lining cures in a few hours, eliminating the wait for new materials.

- Long lifespan - Epoxy liners typically last 50+ years.

- Maintains flow - The smooth internal surface optimises drainage.

- Added strength - Reinforces existing pipes prone to cracks or tree roots.

- Versatile - Suitable for sewer, stormwater, gas and other pipes.

- Eco-friendly - Recycles the existing pipe so no waste.

- Prevents future damage - Seals leaks and resists corrosion.

- Boosts water pressure - By removing obstructions, it enhances flow.

When old pipes, including those made of galvanised iron, clay or concrete, show signs of deterioration, contact our team to see if relining is the best option.

When is Pipe Relining The Best Option?

Pipe relining is often the best solution when:

- The pipes are located under landscaping, pathways, driveways or other surfaces that are costly or difficult to demolish and repair.

- The pipe damage is not severe enough to necessitate full replacement.

- Accessibility is limited due to the pipe location in tight or confined spaces.

- The pipes, perhaps featuring a broken pipe section, are in environmentally sensitive areas where excavation and construction impacts must be minimised.

- There are property access issues due to neighbouring buildings, fences or other obstructions overhead.

- The piping requires frequent repairs and relining is a reliable long-term solution.

- Replacement is too costly but essential piping restoration is required.

- The piping runs under slabs or foundation footings that cannot be disturbed.

Our team assesses each customer’s unique situation to get the job done efficiently, determining if relining is preferable to replacement. We evaluate pipe materials, damage severity, access constraints, and costs to inform our recommendations.

Our modern trenchless relining services offer effective pipe repair solutions across Sydney. Contact our Coogee plumbers and plumbing electrical specialists today for professional advice on whether your sewer lines are suitable candidates for no-dig relining instead of traditional replacement methods.

Signs Your Pipes Need Relining

There are several telltale signs that indicate your pipes may be in poor condition and require relining:

- Frequent blockages - If you’re experiencing regular clogs and slow drains, debris and roots may be intruding in damaged pipes.

- Reduced water flow - Lower than normal water pressure and flow rates, especially during peak usage times, can signify obstructed pipes.

- Persistent leaks - Slow drips and leaks point to cracks or corrosion allowing water and gases to escape pipe walls.

- Musty odours - Sewer gas smells indoors often result from cracks or loose joints in your drain pipe.

- Large sinkholes - Collapsing soil above pipes may be due to leaking joints or extensive corrosion.

- Backed up drains - Standing water and drain backups after rain may indicate a blocked sewer drain or damaged storm water pipes.

- Rust flakes in water - Rusty particles in your water supply can arise from corroding galvanised iron pipes.

Catching deteriorating pipes early and initiating a relining pipe process proactively helps avoid more costly repairs down the track. Even if you’re unsure of the damage extent, our team can inspect pipes with CCTV drain cameras and advise the best solution.

Act before a plumbing emergency arises. Our Sydney plumbing experts can assess whether pipe relining can restore your system, saving you from the mess and cost of replacement.

Frequent blockages - If you’re experiencing regular clogs and slow drains, debris and roots may be intruding in damaged pipes.Comparing the Cost of Pipe Relining vs Replacement

When it comes to addressing all your plumbing needs, pipe relining provides significant cost savings compared to full pipe replacement:

- Pipe relining costs approximately $80 - $250 per linear metre, while drain replacement can average $200 - $500 per linear metre.

- A typical 60 metre house sewer line would cost $4,800 - $15,000 to reline, versus $12,000 - $30,000 to replace.

- Relining is 50-80% cheaper than replacement when you factor in restoration expenses - no need to repair excavated gardens, pathways or driveways.

- Ongoing costs are lower too - relined pipes have a 50+ year lifespan matching PVC so no need for frequent repairs or replacement.

While relining is not suitable for severely damaged pipes, it offers more cost-effectiveness than pipe replacement, particularly for restoring functional pipes suffering from age-related wear and tear. The minimal digging and demolition provides major cost savings.

We offer a wide range of quotes on recommended repairs so you can compare between pipe relining and traditional replacement costs for your specific property. Protect your plumbing and your hip pocket; contact us today to learn more about our relining service for affordable pipe relining.

The Pipe Relining Process Step-by-Step

The pipe relining process involves the following key steps:

- First, a CCTV drain camera inspects the inside of the pipe to locate any damage or obstructions.

- The pipe is cleared of any roots, grease buildup or other debris to prepare it for relining.

- A felt liner tube drenched in epoxy resin is inserted and expanded against the inner pipe walls.

- Hot water, steam, UV light, or ambient air temperatures are used to cure the epoxy resin, solidifying the liner.

- Once cured, the new epoxy liner forms a smooth, jointless and corrosion-resistant pipe lining within the old pipe.

- Any connections to the main pipe, like joins or branches, are reinstated to restore full functionality.

- A final CCTV inspection checks the relined pipe for quality assurance and confirms normal water flow.

the no-dig pipe relining process was very efficient, often completed in one day with minimal disruption to your home. Contact our team today to learn if your pipes are suitable for trenchless relining instead of traditional replacement methods.

Longevity and Durability of Relined Pipes

One of the greatest benefits of pipe relining is the exceptional longevity and durability of the epoxy liners used in creating your new pipe. Compared to the typical lifespan of traditional piping materials:

- PVC pipes last around 50 years before needing replacement.

- Galvanised steel pipes last 30-50 years depending on water chemistry.

- Concrete pipes last 70 years but joints often fail sooner.

- Clay pipes last 50-100 years but the glazing often deteriorates.

Quality epoxy liners that can be used in pipe relining are expected to last at least 50 years, similar to PVC. The seamless epoxy material of the system can resist root intrusion, corrosion, leaks and buildup that leads to blockages.

Relined pipes reinforce the existing pipe structure and prevent future damage. Cracks and gaps are sealed to stop ingress of tree roots which commonly invade ageing drain pipes. The smooth epoxy finish also optimises water flow.

Pipe relining solves immediate issues with your pipe system while also investing in the long-term integrity and performance of the pipes. Contact our Coogee plumbing team to learn more about achieving decades of durability through trenchless pipe relining instead of traditional pipe replacements.

Pipe Relining Materials and Technological Advancements

Pipe relining utilises advanced epoxy resins that have been engineered for long-term durability and performance inside pipes. The key materials used include:

- Epoxy resins - Two-part epoxy is used to impregnate the liner material. It cures to form a solid, jointless pipe lining able to withstand decades of use.

- Non-woven felt liners - Made from needled polyester, PET or glass fibres, these flexible liners form the inner wall of the relined pipe.

- Woven and knitted fabrics - Used for larger diameter pipes, these polyethylene or polyester fabrics provide strength.

Recent advances in epoxy chemistry allow relining to handle temperatures up to 140F, protecting your drains even in hot water lines. UV light-cured resins reduce curing times to under an hour. 3D laser profiling of pipe damage enables precise measurement for custom liner sizing.

Current technology allows robotic devices to install smaller diameter liners with precision. CCTV inspection equipment improves ability to assess suitable pipes. Materials science advances enable liners to flex without compromising strength.

At our plumbing company, we stay abreast of the latest industry innovations in no-dig pipe reparation. We only use proven epoxy systems and installation methods to deliver long-lasting pipe repairs for our valued customers across Sydney.

Maintaining and Caring for Relined Pipes

Relined pipes offer a relining permanent solution requiring minimal maintenance thanks to their durable epoxy construction. However, some simple care measures suggested by your plumber will help maximise their lifespan and performance:

- Make sure to avoid pouring fats or harsh chemicals down drains - These can adhere to the liners and cause blockages over time.

- Install basket strainers in sinks - Catches food scraps and debris before entering pipes.

- Flush pipes with water after floor drains are used - Prevents buildup of sediment.

- Periodically test for leaks - Can identify minor issues before major pipe failures.

- Trim back invasive tree roots - Aggressive roots can still penetrate joints and connections.

- Clean out downpipe or drain filters - Prevents stormwater system clogs leading to leaks.

- Consider follow-up CCTV inspections - Helps identify potential damage issues early.

High pressure jet cleaning should not be used on relined pipes from nodig pipe repair as the force can damage the epoxy liner. Chemical root killers are also not recommended as they may weaken the liner bonds over time.

Following a regular maintenance schedule extends the lifetime of your relined plumbing. Regular professional inspections can help catch any leaks or obstructions in pipes before major problems arise. Our team is very happy to provide follow-up maintenance checks on pipes we have relined inside your home.

With proper preventative care, relined pipes will continue working like new for decades, avoiding the need for expensive replacements. Contact Our Sydney plumbing specialists are available anytime for tips on caring for your relined pipes, meeting all your plumbing needs.

Frequently Asked Questions About Pipe Relining

What are the main benefits of pipe relining?

Pipe relining is a cost-effective, minimally invasive solution tailored to your plumbing needs; designed to repair and restore old, damaged pipes. Key benefits include avoiding expensive and messy pipe replacement, preventing future damage, restoring water flow, sealing leaks without need, and reinforcing pipe integrity for decades.

What types of pipes can be relined?

Our pipe relining services our customers trust can handle various types such as sewer pipes, drain lines, galvanised pipes, stormwater pipes, and more. If your pipes are structurally sound but show signs of damage like cracks or root intrusion, relining is often an appropriate repair method.

How long does the relining process take?

After inspection, Liner installation in pipes, sewer or otherwise, can take just 2-3 hours.

Curing and setting of the epoxy liner is complete within 3-4 hours. Curing and setting of the epoxy liner is complete within 3-4 hours. Pipe relining is a quick process, usually completed in one day.

What is the typical cost of pipe relining?

The cost of pipe relining is significantly less, often around 50-80% less than full drain replacement. On average, pipe relining costs $80 - $250 per linear metre while pipe replacement averages $200 - $500 per metre. Exact costs depend on pipe size, length, location and damage.

How long do relined pipes last?

High quality epoxy liners used in relining have an expected lifespan of 50+ years. The tough, corrosion-resistant epoxy material resists damage, leaks, and blockages far better than older pipe materials.

Will I have to excavate around my pipes?

A key benefit of relining is that it is a no-dig process requiring no excavation or destruction of surfaces. Access to pipes is gained through cleanouts and drain lines so you avoid costly restoration work.

What does the pipe relining process involve?