p>p>p>p>p>

Pipe Relining is Too Expensive Compared to Replacement

One myth about pipe relining is that it costs more than simply replacing the pipes. However, this is often not the case. While pipe relining may have higher upfront costs compared to replacement, it saves money in the long run.

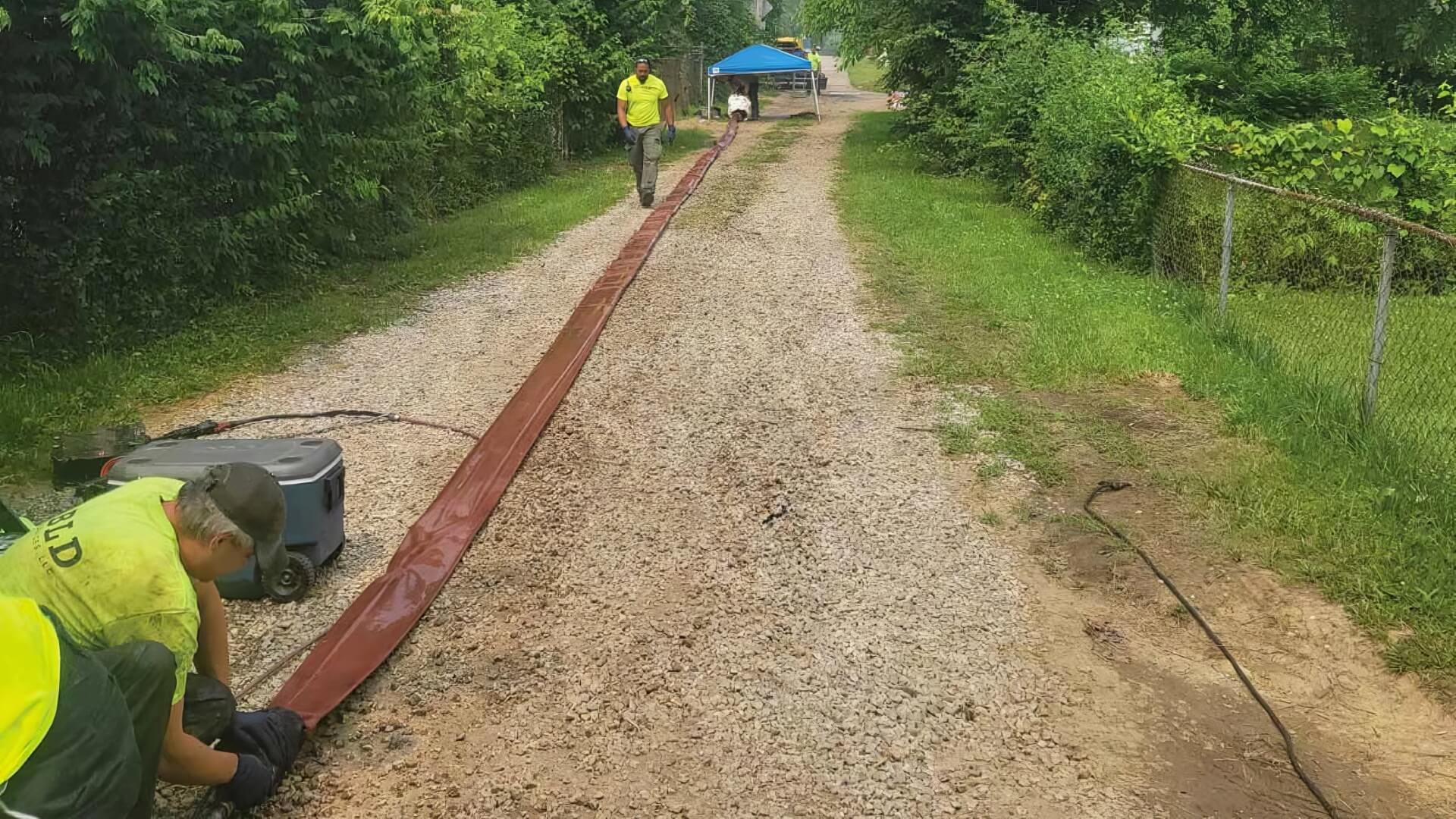

Full pipe replacement requires excavating the ground to access and remove old pipes. This entails high costs for demolition, removal of the old pipes, installing new pipes, and repairing the surrounding areas that were dug up. Pipe relining avoids all these costs by using trenchless technology that requires no ground excavation.

Though relining has a higher initial price tag, the overall costs are lower compared to replacement when factoring in the expenses of digging, new materials, and restoration. Relining also avoids the mess and disruption of digging up your property.

Relined pipes have a longer lifespan than replaced pipes. Newly installed pipes may last around 50 years, but relined pipes can extend the life of your old pipes by another 50 years. This avoids future replacement costs down the road.

In most cases, pipe relining provides superior value over the long term. While costs should always be weighed carefully, dismissing relining as too expensive ignores its many economic benefits compared to replacement.

Pipe Relining Doesn’t Work on Old Pipes

p>p>p>p>p>p>p>p>p>p>p>p>p>p>p>

Pipe Relining Doesn’t Last Very Long

Another common myth about pipe relining is that it does not last very long compared to replacing pipes. However, this perception is misguided. Modern pipe relining uses high-quality epoxy resins that can extend the life of ageing pipes for decades.

The epoxy materials used in pipe relining are durable, corrosion-resistant, and can last for over 50 years when applied correctly. Proper surface preparation, professional installation, and curing are key to achieving long-lasting results. The epoxy bonds firmly to the inside walls of pipes, essentially creating a pipe within a pipe.

Unlike traditional pipe replacement, relining avoids repeatedly digging up and replacing pipes over time. The long-lasting epoxy materials provide a permanent solution without ongoing maintenance costs down the road. As long as the existing pipe structure remains intact, the epoxy liner will keep performing for many years to come.

While no solution lasts forever, high-quality pipe relining comes close. With proper assessment and installation, relined pipes often outlast replaced pipes. When it comes to longevity, pipe relining is a smart, long-term investment compared to replacement.

Pipe Relining Can Damage Your Plumbing System

One myth surrounding pipe relining is that it can actually damage or compromise your plumbing system. However, when done properly by experienced professionals, pipe relining is a very safe and effective repair method.

During the relining process, no pipes are removed or replaced. A flexible epoxy resin coating is applied to the interior of pipes, leaving the existing plumbing structure intact. This negates the risk of weakening or disrupting your pipes that comes with full replacement projects.

High-quality epoxy resins are non-toxic once cured and will not contaminate your water supply. Proper surface prep ensures the epoxy bonds firmly to pipes without leakage or deterioration. The materials and techniques used in modern relining are designed to reinforce and extend the life of your pipes.

An experienced, reputable contractor will conduct thorough inspections first, only recommending relining for structurally sound piping. Minor repairs may be required beforehand to ensure success. With proper assessment and installation, relining poses no risk of damage.

In fact, relining can prevent further damage from intrusive root growth, corrosion and more. It’s a safe, non-invasive alternative to full replacement that preserves your existing plumbing infrastructure.

Proper Assessment is Critical Before Relining

Before undergoing pipe relining, a thorough assessment should be conducted by a qualified professional. Proper assessment is important to determine if pipes are suitable for relining or if full replacement is necessary.

The plumber will use CCTV camera inspection to examine the interior condition of pipes. The footage lets them check for any serious damage, obstructions, or misalignments that could prevent successful relining. They also inspect to ensure the existing pipe walls are structurally sound.

If the pipes are too deteriorated or misaligned, the epoxy may not adhere correctly during lining. Any major blockages or obstructions need clearing prior to relining as well. Identifying and addressing these issues through proper assessment prevents failures down the road.

The assessment also verifies what pipe types and sizes are present. The dimensions must be measured precisely to custom-fit the epoxy liner. Knowing the layout helps determine the best relining method and equipment to use.

By thoroughly examining the pipes beforehand, the plumber can advise if lining is feasible or if full replacement is the better solution. Proper assessment and open communication ensure expectations are aligned, so there are no nasty surprises after relining begins.

While pipe relining can fix a multitude of issues, it isn’t a magical cure-all. Proper assessment remains important to avoid misapplying relining where replacement is truly needed. This prevents wasted time, money, and frustration for all parties involved.

Regular Maintenance Ensures Longevity

p>p>p>p>p>p>p>p>p>p>p>p>p>p>p>p>p>p>p>p>p>

High Quality Epoxy Can Last Over 50 Years

One of the biggest myths surrounding pipe relining is that it doesn’t last as long as fully replacing pipes. However, with high quality epoxy resins, relined pipes can easily last over 50 years.

Modern epoxy materials used in relining are extremely durable and corrosion resistant. When properly installed, the epoxy liner bonds firmly to the inside walls of the pipe, protecting it from further wear and degradation.

Quality epoxy liners are designed to withstand decades of use, abrasion from flowing water, and exposure to various soils and temperatures. As long as the host pipe remains structurally intact, the epoxy liner will keep performing year after year.

Proper surface preparation and full curing time ensures maximum longevity of the epoxy liner. An experienced contractor will use the optimal thickness and number of coats tailored to your specific pipes.

While no solution lasts indefinitely, high-end epoxy liners certainly come close. With regular maintenance and inspection, quality relined pipes often outlast replaced pipes in terms of lifespan.

Pipe relining with top-tier epoxy is an investment that pays off over time. For pipe repairs that keep performing for over half a century, it’s clear that not all liners are equal in durability.

Pipe Relining is a Safe and Effective Solution

p>p>p>p>p>p>p>p>p>p>p>p>p>p>p>p>p>p>