Introduction to Gas Fitting in Kitchen Renovations

Engaging professional gas fitters is essential for a kitchen renovation in Coogee. Gas appliances such as cooktops, ovens, and hot water systems need specialised installation, repair, or replacement. Unqualified individuals risk causing gas leaks, fires, and regulatory non-compliance.

As a leading plumbing and gas fitting company serving Coogee for over 10 years, Coogee Plumbing emphasises safety and reliability. Our licensed gas fitters conduct inspections of existing lines, design new layouts, and connect and test appliances, always adhering to current gas fitting regulations.

Gas is favoured by Coogee homeowners for its cost-effectiveness, efficiency, and convenience. Strategically placing gas appliances and planning for gas line installation early are key steps for a flexible approach to kitchen renovations.

This guide details essential gas fitting services at every kitchen renovation stage, ensuring the flawless function of your new kitchen.

Importance of Hiring Certified Gas Fitters

It’s imperative to hire certified gas fitters for kitchen renovations to meet safety standards and legal requirements. In Australia, a valid gas work licence is mandatory for anyone undertaking gas fitting tasks.

Energy Safe Victoria reports that weekly, improper gas appliance installation results in 20-30 house fires and 10-20 gas leak emergencies. Employing non-certified workers brings about the risk of leaks, explosions, exposure to carbon monoxide, and fires.

Gas fitters at Coogee Plumbing undergo extensive training to become certified, updating their knowledge on the latest industry best practices and safety standards through yearly CPD training.

We manage gas line inspections, layout designs, appliance connections, and leak testing, guaranteeing the safe and reliable functioning of your new gas appliances.

Typical Gas Fitting Tasks in Kitchen Remodels

Typical gas fitting jobs when renovating kitchens in Coogee include:

- Inspecting and testing existing gas lines for leaks or issues using advanced detection equipment

- Designing and planning new gas line layouts to optimise placement of appliances

- Rerouting, extending or installing new gas pipelines to feed new cooker or hot water system locations

- Connecting gas appliances, including cooktops, ovens, and hot water systems, to the gas network

- Conducting safety checks and leak tests on all new gas connections and appliances

- Ensuring compliance with all legal gas fitting codes and standards throughout

Our gas fitters meticulously shut off supply at isolation valves during installations and conduct detailed inspections of valve seals, pipe joints, and appliance functions to guarantee safety.

Coogee Plumbing’s licensed technicians, with over a decade’s experience, carry out all gas fitting works for kitchen renovations, ensuring compliance with Australian standards and optimal safety.

Installing New Gas Pipes and Appliances

When installing new gas pipes and appliances in a Coogee kitchen, using a licenced professional gas fitter is crucial.

- The first step involves designing the new gas layout to map optimal pipeline routes and appliance positions. Gas fitters use specialised tools to draw 3D schematics.

- Next, piping is extended from the gas metre to the planned appliance locations. Our experts measure, cut and join copper pipes using manual techniques and pipe threaders.

- Isolation valves are inserted at key joints to enable gas flow control. These automated shut-off switches prevent leaks in emergencies.

- The gas fitter then connects cooking appliances like cooktops and ovens, as well as hot water systems, routing gas lines directly into the rear of each unit.

- Connections involve tightening gas fittings and securing the appliance. Leak detection tests using non-toxic gases check for seal breaches around joins.

- The final step is relighting pilot flames and testing ignition, burners and functionality. Adjustments ensure uniform flame shape, height and temperature.

Gas fitting expertise includes system design, pipe installation, appliance integration, and leak prevention. Coogee Plumbing’s gas fitters manage the complete process, upholding the strictest safety and performance standards.

Repairing, Servicing, and Maintaining Safety

Regular servicing and repairs by qualified gas fitters are essential for the ongoing safety of your new Coogee kitchen’s gas appliances and fittings.

Annual servicing spots problems such as gas leaks, malfunctioning valves and seals, flame inconsistencies, or corrosion. Prompt minor repairs avert these issues from becoming significant hazards.

It’s vital that the gas fitter inspects all pre-existing gas piping servicing appliances during your kitchen refurbishment. Old pipes risk cracks or joint failures. We use ultrasonic leak detectors and pressure gauges to test integrity.

For new installations, Coogee Plumbing provides a complimentary first-year service to assess pipes, connections, and appliance functioning. This identifies any defects in materials or workmanship.

We recommend that homeowners schedule annual maintenance checks, particularly before the colder months, to keep their gas systems in good working order and compliant with Australian safety regulations.

Safety Protocols for Gas Appliance Installations

Strict safety protocols protect against risks when Coogee Plumbing gas fitters install or replace appliances. We take zero risks through rigorous planning, safe work procedures and extensive testing.

Before any physical works commence, we consult the Dial Before You Dig hotline to identify buried electricity cables, gas mains, water pipes and other services onsite. Our technicians assume nothing about hidden infrastructures.

We methodically assess your existing gas system’s capacity to handle additional load from new ovens or cooktops. Piping and metre upgrades often precede appliance installation jobs.

During appliance connections, specialised tools guarantee uniform torque on fittings, followed by ultrasonic gas detectors examining all seals and junctions meticulously. We conduct repeated ignition tests on newly installed appliances to confirm all requirements for flame operation, temperature, and combustion levels are met without further adjustments.

Your safety remains our priority. Our structured installation process and diagnostic checks ensure seamless gas appliance performance for years following your Coogee kitchen renovation.

Planning Gas Connections in Your Remodel

Careful gas connection planning is crucial during a Coogee kitchen renovation. New cooktops, ovens and hot water systems require significant lead times for appliance deliveries and gas fitting works.

Ideally, consult Coogee Plumbing’s gas fitting team during the initial design phase before FINALISING layouts. We provide expert advice on optimising pipeline routes, appliance placements and synchronising timelines with other trades like electricians, carpenters etc.

Allow 2-3 weeks for gas cooktop installations and roughly 5 days for connecting instant gas hot water systems, subject to model availability and gas line capacity.

Inadequate coordination between electrical and gas-related activities can cause project delays, such as when installing new circuit boxes, laying wires, and positioning pipes compete for space.

Engaging our gas fitting team early allows us to create cohesive project plans that streamline efforts, cut expenses, and secure prompt connections for your kitchen’s gas appliances.

Consulting Services Before Excavation

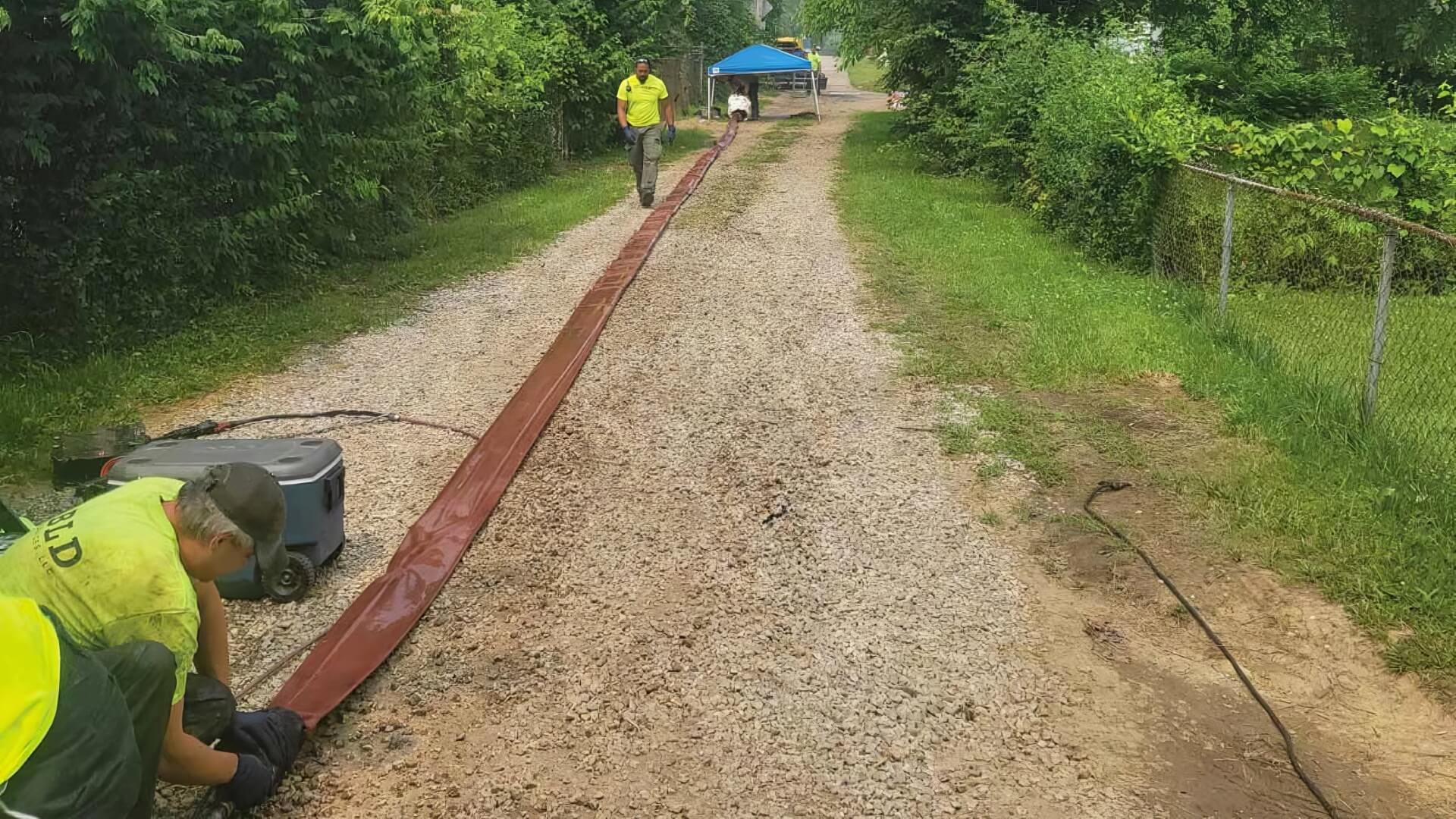

Excavation risks damaging underground infrastructures like gas pipes, so consulting services beforehand is crucial. Coogee Plumbing uses Dial Before You Dig to request detailed site plans showing subsurface pipes, cables and mains.

This preventive measure identifies existing gas lines to prevent rupture, avoiding the substantial inconveniences and safety hazards from leaks that could impact your home and local businesses. We reference utility plans daily to avoid such risks.

However, outdated records sometimes show inaccurate pipe positions. We carefully hand-expose sections before mechanical digging, reconfirming routes. For entirely new gas installations, our technicians assess intended trench routes, considering soil conditions and signs of other underground utilities.

Through best practises like consulting reference plans and prudent excavation, Coogee Plumbing gas fitters conduct underground works safely. We take all precautions necessary to avoid damaging surrounding infrastructures when installing or extending gas piping during your renovation.

Avoiding Service Interruptions During Renovation

When renovating your Coogee kitchen, it often continues using existing gas appliances like cooktops and ovens during early works. We avoid unnecessary service disruptions through careful planning.

For most renovations, retaining full gas functionality remains crucial for owners still occupying homes. Our gas fitters use non-destructive techniques to install new piping around current kitchen layouts.

We assess appliance positions early, designing new networks that integrate into the old. New lines are pre-built, then rapidly interchanged once old sections are isolated. This reduces connection downtime to under 30 minutes in most homes.

During the final kitchen fitout, which might be similar to commercial plumbing tasks, appliances like cooktops simply disconnect and swiftly reconnect once benchtops are installed. We allow gas to flow immediately after stovetops are secured, letting homeowners continue cooking meals.

Thanks to careful planning and quick-changeover techniques, Coogee Plumbing’s gas fitters ensure consistent gas supply throughout most of the kitchen renovation.

Upgrading Gas Appliances: Cost and Efficiency Benefits

Switching to contemporary gas appliances offers notable cost savings and improved efficiency for homeowners. Replacing outdated cooktops, ovens and hot water systems with new gas models reduces energy bills and carbon emissions.

The Clean Energy Council of Australia notes that natural gas hot water heaters and space heaters produce around 30% fewer greenhouse gases than their electric counterparts. Furthermore, modern gas cooktops boil water approximately twice as fast, consuming more than 40% less energy.

New gas appliances incorporate precise burners and heat exchangers that maximise fuel utilisation. Flue heat recovery transfers warmth back into homes, decreasing heating expenses. Additionally, sophisticated electronic ignition systems enhance both safety and dependability.

While upgrading major gas appliances costs approximately $2000 to $4000, owners recover outlays through ongoing utility savings. Coogee Plumbing offers discounted installations with our kitchen renovation services. Upgrading provides years of energy efficiency alongside the superb performance of natural gas.

Conclusion: Why Not to DIY Gas Fitting

After covering the integral role gas fitting plays in kitchen renovations, the dangers of DIY gas work should be abundantly clear. Handling gas appliances, lines and connections requires extensive training, certification and field expertise for safe outcomes.

DIY gas fitting attempts pose threats of gas leaks, fires, carbon monoxide exposure, damage to appliances, and potential fines for non-compliance. Except for basic tasks like igniting pilots, all gas jobs should be left to qualified technicians.

Coogee Plumbing remains the premier local gas fitting specialist for kitchen renovations. Our certified and insured professionals ensure that your new gas appliances and systems are expertly designed, installed, and fine-tuned for utmost safety.

To discuss your upcoming kitchen renovation and gas requirements, email Coogee Plumbing or call 1300 349 338 today to book your free quote and consultation.